Properties: Semiconductor, high shock resistance, optical

Application: ceramic, refractory, optical, magnetic materials, chemical industries, catalysts

It belongs to the family of inorganic compounds with the chemical formula Al2O3. This oxide is an important amphoteric oxide and has various trade names such as alumina, corundum and… has it. The various trade names of aluminum oxide indicate the wide range of uses of this material in the industry.

Alumina also exists as other phases. which they name based on Greek letters. These phases are θ, γ, ρ, α, χ, η. Each of these phases has its own crystal structure and characteristics. Of course, all these phases are intermediate and unstable phases. After heating alumina and forming these phases, α phase is finally formed.

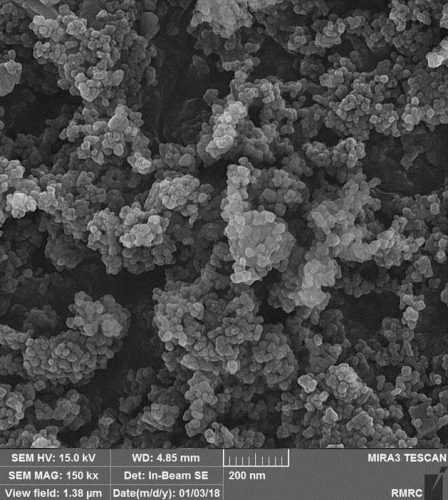

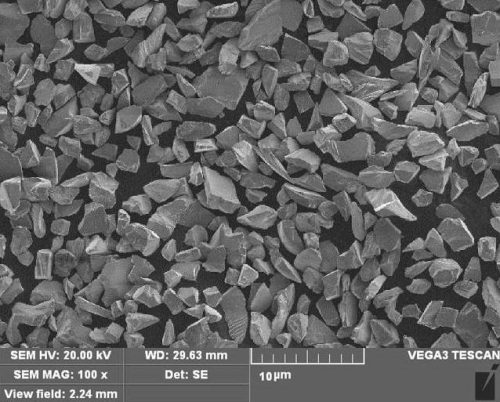

The transformation temperature of alpha alumina is theoretically 1200 degrees Celsius, while experimentally this temperature is close to 1400 degrees Celsius. On the other hand, the critical growth temperature of alumina grains is 1000°C, thus, at high temperatures such as 1400°C, it is not possible to expect alumina with a low grain size (1 to 5 microns) to be produced directly, and usually, conventional methods of mechanical milling They use it for this. By mixing the synthetic and innovative sinter aid of this technological unit, we managed to reduce the calcination temperature of alumina to 1050 degrees Celsius. This causes the production of alpha alumina with small grain size to be produced directly, and there is no need for intermediate processes such as de-agglomeration and mechanical milling, as a result, production costs are reduced.

For the production of alpha alumina in a 100% single phase, nearly 1 year of research and development work was done. The biggest challenge in the production of this material is the high transformation temperature as well as the stability of the intermediate phases before alpha alumina. By inventing an additive, Raika Sanat Efarand company succeeded in producing this product at a lower temperature. Other advantages of Rasa aluminum oxide powder include the following:

100% phase purity (alpha alumina single phase)

99% chemical purity

Competitive price

Production in different sizes and phase purities according to the customer’s request

Applications of alumina powder:

Ceramic tile industries: glaze, sanitary ware porcelain, tile biscuits

Refractory industries: refractory brick, refractory mass

Ceramic parts industries: types of ceramic liners

Abrasive industries: ceramic ball, surface polishing

Polymer, rubber and paint: thermal insulation

Applications of alumina in the ceramic industry

The unique properties of aluminum oxide include high melting point, wear resistance, thermal shock resistance and thermal insulation. Alumina applications are very wide due to the excellent and unique properties of this composition. In ceramic engineering, alumina plays the role of the driving force and the right hand of an engineer. Alumina is used in all cases, from the smallest laboratory equipment such as boats, ball mill balls, heat-resistant containers, laboratory powders, etc. to glass making and spacecraft bodies. Applications of alumina in engineering ceramics are many. Engineering ceramics refers to advanced or technical ceramics that are used in tech industries. These engineered ceramic materials are made for applications in harsh environments that require increased wear resistance, thermal and chemical stability, and possess many of the other properties of alumina. Engineering ceramics have applications in chemical and medical, industrial, electrical, etc. industries. Alumina is also often used in the production of glass products and makes the glass stronger and more transparent. It has even been studied for its potential in creating unbreakable glass.

Applications of alumina in the steel industry

One of the most important features of aluminum oxide is fire resistance and thermal shock resistance. This property has caused the applications of alumina in the steel industry as walls and refractory bricks. The melting point of alumina is much higher than the melting point of steel and does not cause a problem for steel production. Due to its hardness and excellent strength, alumina is used in all kinds of industrial abrasive materials. Likewise, alumina can be used as a method of wear protection.

Although alumina is mostly known as a raw material in the production of aluminum, it also plays a major role in many industrial applications, from abrasive materials to engineering ceramics. Although the production of alumina from bauxite is quite simple, complex steps are required to produce pure alumina.