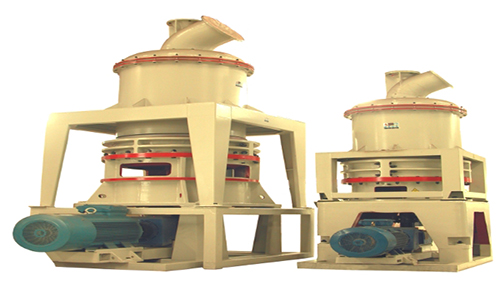

Raymond mill is one of the modern crushing technologies, which is mainly used for crushing non-flammable and explosive stones in the mining, metallurgical and chemical industries. Raymond mill is used to grind minerals with a hardness of less than 6 mos, such as bentonite, feldspar, calcite, calcium carbonate, gypsum, iron ore, etc. from mesh 80 to 400. Raw materials are poured into the input hopper of the machine. These materials, which are less than 2 to 3 cm in size, are fed to the inner chamber of the mill with the help of a conveyor belt or screw. The centrifugal force caused by the rotation of the main shaft of the mill directs the material to the space between the roller and the ring. In the lower space of the mill, shovels are connected to the main shaft, which are responsible for guiding the material from the bottom of the mill to the space between the roller and the ring. The presence of high-pressure springs exerts a lot of force on materials and crushes them. Placing the centrifugal fan in the closed circuit of the mill leads to the creation of negative pressure in the mill space and directs the fine particles to the classifier of the machine. The centrifugal force caused by the classifier cycle returns the large particles to the mill for re-shredding and allows the crushed particles to pass to the cyclone for separation from the air. Finally, the dust created by the filter bag is collected.