Properties: high mechanical resistance, high melting point

Applications: refractories, furnace refractories, casting masses, surface operations

Introduction to silicon carbide

Silicon carbide or silicon carbide or carborundum with the chemical formula Sic is a rare mineral in nature. This substance is a crystalline solid and its pure samples are usually colorless and transparent. If some impurities such as aluminum or nitrogen are added to silicon carbide, its color will turn green or blue depending on the amount of added impurities. This material is made of a combination of silicon and carbon, and due to its properties such as high mechanical resistance, semi-conductor, and also being ceramic, it is used in many industries, especially the industries of high voltage and fast response devices.

Silicon carbide was first discovered in 1891 by Acheson and is currently recognized as one of the most important and widely used industrial ceramic materials in the world. Today, this material is used as an additive in the production of steel, ceramics and abrasive materials. Currently, in order to use this substance in different industries, its production is done in three ways, which are:

Nitride Bonded Silicon Carbide (NBSC)

Porous Silicon Carbide (SSC)

Reactive Silicon Carbide (RBSC)

Of course, the production of this material is done in different forms, such as clay bonded carbide and deposited silicon carbide, which are less useful.

Silicon carbide production methods

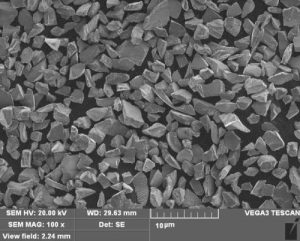

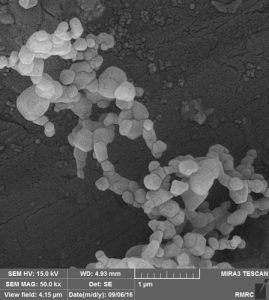

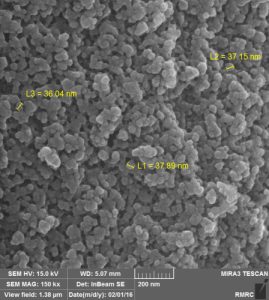

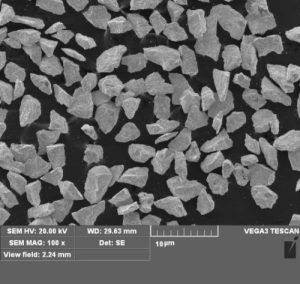

As mentioned, silicon carbide is a very rare and rare mineral, and due to its widespread use, today its production is done artificially and by synthesis. Since 1893, its powder has been mass-produced completely artificially and is used to make abrasive materials. The synthetic method or the Acheson method is known as the artificial method of silicon carbide production, and in this method, pure silicon is first combined with ground petroleum coke or quartz sand (carbon) in an electric resistance furnace, and then it must be heated to a temperature of 2500 degrees Celsius. . This material is usually produced in the form of a fine powder and is black or green in color, of course, its color will largely depend on the quality of the raw materials.

It is necessary to know that all the silicon carbide in the world is produced by the same artificial method and there are very small amounts of it in nature and only in some meteorites. The production of this material is also done in the form of ingots and it is widely used in various industries.

Silicon carbide

Uses of silicon carbide

In general, silicon carbide is used in the production of many refractory products and abrasive materials, and now we intend to examine the uses and uses of this material in industries in a more detailed manner. In general, the uses and uses of this material are as follows:

Can be used to produce hard ceramics, especially ceramic plates for bulletproof vests

Can be used to produce all kinds of cutting and abrasive tools

Can be used to make acid washing machines

Can be used to produce plants for smelting industries

Can be used to produce telescope mirrors

Can be used in steel industries

Can be used in the jewelry industry

Can be used in the production of graphene

Can be used in nuclear industries

Can be used to print carborundum

Can be used in quantum physics

Can be used to make all kinds of LEDs

Can be used to produce heating elements

Can be used to produce fishing hook guides

Can be used to make car brakes and clutches

Can be used to produce electrical systems

And…

Physical and chemical properties

Silicon carbide is considered one of the most widely used chemicals in the world due to its special physical and chemical properties. The physical and chemical properties of this material are as follows:

Very high temperature resistance

Very hard

High corrosion resistance

It has a density of 3.21 grams per cubic centimeter

Semiconductor

It has a hexagonal or cubic crystal structure

Completely neutral and stable (chemically)

Introduction of silicon carbide family products

Regarding the products of the silicon carbide family, it should be said that this material is usually used alone and there are usually no special alloys of it. Of course, it should be noted that in some industries, barium and chromium can be added to its composition as binders. However, only silicon carbide itself is used in abrasives production industries, and its other combinations with other chemicals are not used in any way.